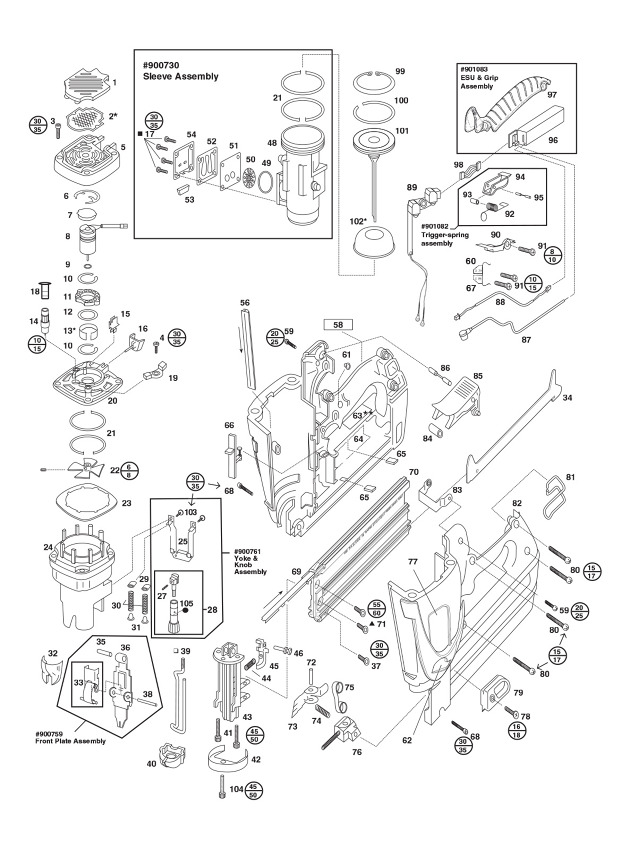

Paslode Im 350 Service Manual

Paslode offers the following repair kits:. 219305 / Cordless Framing Tune Up Kit for 900420 (IMCT).

Paslode Im350

219304 / Cordless Trim Tune Up Kit for 900,901000. 219218 / For OLDER Model 5000 Series.

219219 / For LATEST Model 5000 Series. 219222 / For 3000 Series.

219235 / For F350S / 501000. 219224 / Trigger Valve Repair Kit for 3000, 4000, 5000 Series, F350S. 219245 / Feeder Claw Repair Kit for P275C, F325C, P350C. 219379 / Cordless Framing Tune Up Kit for 902200 / 902600 (CF325/CF325Li).

219352 / For PF350S / 502000 The kits can be purchased at a sales location nearest you or online:. Paslode offers Tune Up kits for Cordless Framing and Trim/Finish nailers. The kits contain 12 oz of degreaser cleaner; 10 ml of cordless tool oil; air filter; fuel stem adapter; spark plug; and Tune Up kit instructions. Tune Up kit part numbers:.

219305 / Cordless Framing Tune Up Kit for 900420 (IMCT). 219304 / Cordless Trim Tune Up Kit for 900600, 902000, 901000. 219377 / Cordless Framing Tune Up Kit for 902200 / 902600 (CF325/CF325Li). 219409 /Cordless Li-ion Trim Nailer Tune up kit 902400 The kits can be purchased at a sales location nearest you or online:.

Paslode Parts Site. Paslode Factory Outlet Store. You can use the following formula to figure out the size air compressor you need: The Number of tools being used x the number of nails each tool will drive per minute x 1.2 (safety factor) x the Amount of Air per Shot (SCFM) at the operating pressure (psi). This number is found on the chart in the tool schematic and parts list provided with the nailer. For example, if you have two F-350S tools each driving 20 nails per minute with the compressor set at 90 PSI you get: 2 x 20 x 1.2 x.082 = 3.95. The compressor needs to deliver 3.95 CFM at 90 PSI.

If you operate the tool at 120 PSI at the same rate the number will be higher: 2 x 20 x 1.2 x.108 = 5.2 CFM. When selecting an air compressor be aware that as the air pressure (PSI) increases, the delivery rate (CFM) goes down. Most compressors will rate the CFM at 50 PSI and at 100 PSI. In general, fuel cells with RED labeling are for Framing nailers and fuel cells with YELLOW labeling are for Trim/Finish nailers and Staplers. There are several things that could cause a nailer to “blank fire”. If your tool does not have a lockout, check that you haven’t run out of fasteners. There may be a nail jam preventing the fasteners from moving forward.

For information on clearing a nail jam click on “Products” at the top of this page, select your nailer and then select the Owner’s Manual PDF Download for your nailer. This information is typically found toward the back of the manual.

You can also check the operations manual that came with your tool. Cordless nailers may require cleaning.

If the tool has driven 10,000 nails or more, it may require cleaning. First remove the fuel, battery and the remaining nails in the magazine. Using the 5/32 hex key, remove the two screws on either side of the work contact. Next grab hold of the work contact with one hand and the bottom of the magazine with the other. Pull the two away from each other and the magazine will separate from the nose. This will allow the jammed nail to fall out. Inspect the driver blade and push it back up into the tool.

The layout for each section is a complete manual covering maintenance, troubleshooting and repair. In addition, the Clymer ProSeries Snowmobile Service Manual 1962-1986 features condensed service data and specifications covering multiple manufacturers and models. Ski doo formula 3 600 manual.

Install the two nose screws. For information click on “Products” at the top of this page, select your nailer and then select the Owner’s Manual PDF Download for your nailer.

Do not attempt to operate or service the nailer until you have read and understood all safety precautions and manual instructions. Disconnect the air and remove fasteners from the nailer when making any adjustments or servicing it.

The F350 Framing nailer has a 3/16 hex key located in the rear of the magazine. To adjust the depth of the nail, loosen the bolt on the work contacting element with the hex key. Raise the work contact up to drive the nail deeper or lower the work contact to drive the nail more flush. Tighten the bolt on the work contact and test the tool.